Views: 0 Author: Site Editor Publish Time: 2025-07-09 Origin: Site

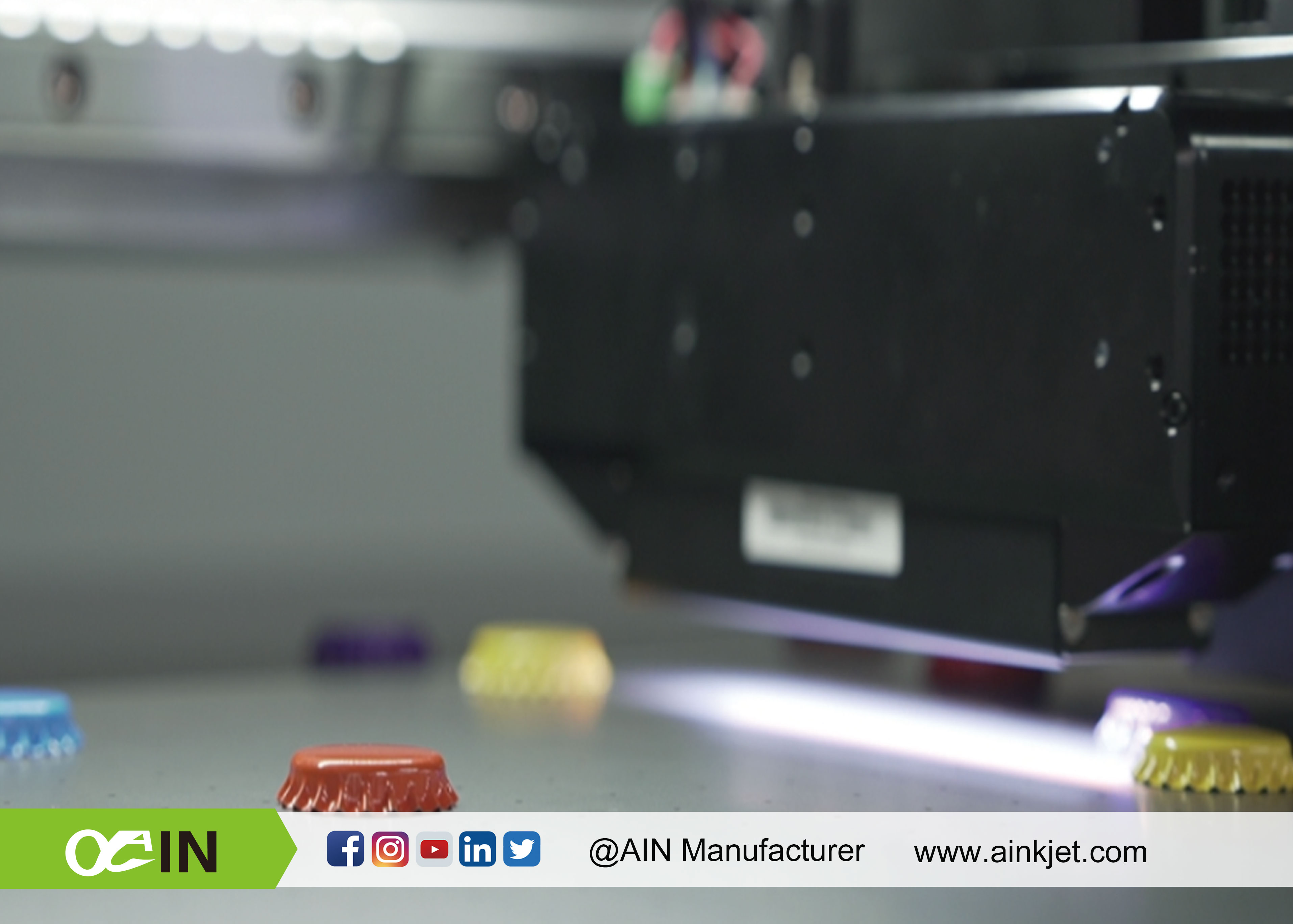

In the field of digital printing, color, speed, and substrate compatibility are key factors, and texture is even more critical. AIN 2.5D texture UV flatbed printing breaks the limitations of flat graphics, adding touchable, raised textures. It is widely used in high-end packaging, Braille logos, and other applications, and is changing the way products are displayed.

What are its advantages? How can it help your business development? Let's explore together.

Learn more about AIN 2.5D Texture UV Flatbed Printing

AIN 2.5D texture UV flatbed printing creates a raised texture effect on the surface by stacking multiple layers of ink, resulting in a three-dimensional and layered pattern. Traditional printing technology creates a two-dimensional image on a flat surface, while AIN 2.5D printing can add subtle depth, imitating relief, engraving, or layering effects.

How does it work?

AIN 2.5D textured UV flatbed printing uses UV-cured ink and multiple printings to precisely control the spraying of UV ink onto the surface of printing materials such as metal and glass, simulating a variety of textures with ink accumulation; the ink is cured by ultraviolet light, fixing the color and enhancing the three-dimensional realism of the pattern; it also supports post-processing such as matte and embossing, and can be customized on demand to achieve unique artistic effects.

Here’s a simple breakdown of the process:

1. Inkjet and overlay: Use UV curing ink to repeatedly apply transparent/white ink in designated areas, and accurately overlay ink layers.

2. Texture simulation: Using UV flatbed printing + 2.5D texture, control the ink spraying onto the surface of metal, glass, and other materials, and simulate various textures by ink accumulation.

3. Curing to shape: UV-LED light cures instantly, ensuring precise builds and sharp edges.

4. Post-processing customization: choose matte, embossing, and other post-processing as needed to create a unique artistic effect.

In what fields is 2.5D printing applied?

AIN's 2.5D UV flatbed printing is versatile and has been used in many industries:

1. Braille and Signage:Print raised durable, and readable Braille directly onto substrates such as acrylic, metal, or plastic - ideal for hotels, hospitals, and public buildings.

2. Luxury packaging and labeling:Adding a premium embossed finish to your cosmetics boxes, perfume labels or product sleeves instantly increases brand recognition.

3. Customized product personalizationDesign smartphone cases, gifts, nameplates, or plaques with tactile logos and patterns that customers can feel and remember.

4. Interior decoration and art reproduction:Realistically simulate brushstrokes, canvas texture, or wood grain on wall art, signage, or decorative panels.

5. Prototypes and Brand SamplesCreate cost-effective packaging mockups or product models with realistic textures and finishes - no tools or molds required.

The main advantages of AIN 2.5D texture UV flatbed printing

1. Rich three-dimensional effect

UV flatbed printer technology combined with 2.5D texture can simulate various tactile and visual textures (such as leather grain, fabric, natural stone, etc.), making the pattern more layered and three-dimensional. Compared with traditional two-dimensional printing, it significantly improves the sense of reality and visual impact.

2. Multi-material adaptation

Can be directly printed on metal, glass, ceramics, wood, plastic, and other materials to expand design freedom.

3. Process flexibility

Supports a variety of post-processing processes such as matte, glossy, embossing, hot stamping, etc., which can be customized and combined to create unique artistic effects.

2.5D textured UV flat panel technology stands out for its high precision, multi-material adaptability, and rich tactile effects, and is widely used in personalized customization and high-end customization markets.

Which AIN printers support 2.5D texture printing?

AJ-9060X4 AI Visual Positioning Digital Inkjet UV flatbed Printer

Integrates CCD visual positioning, no manual calibration, boosts efficiency, cuts costs, simplifies processes; offers 2.5D texture UV printing, achieves 3D effects, multi-material adaptation, multi-functional, intelligent and efficient, suitable for signage, packaging, decoration, etc.

|  |  |  |  |

AIN 2.5D UV Printing: New Tactile

AIN 2.5D textured UV flatbed printing brings breakthroughs in traditional printing possibilities to various industries with its unique three-dimensional touch, wide material adaptability, and flexible process, adding dimensions to printed products, helping companies seize the initiative in the personalized and high-end customization market, and opening up a new printing touch experience.