| Availability: | |

|---|---|

| PDF Export | |

Printer Informations

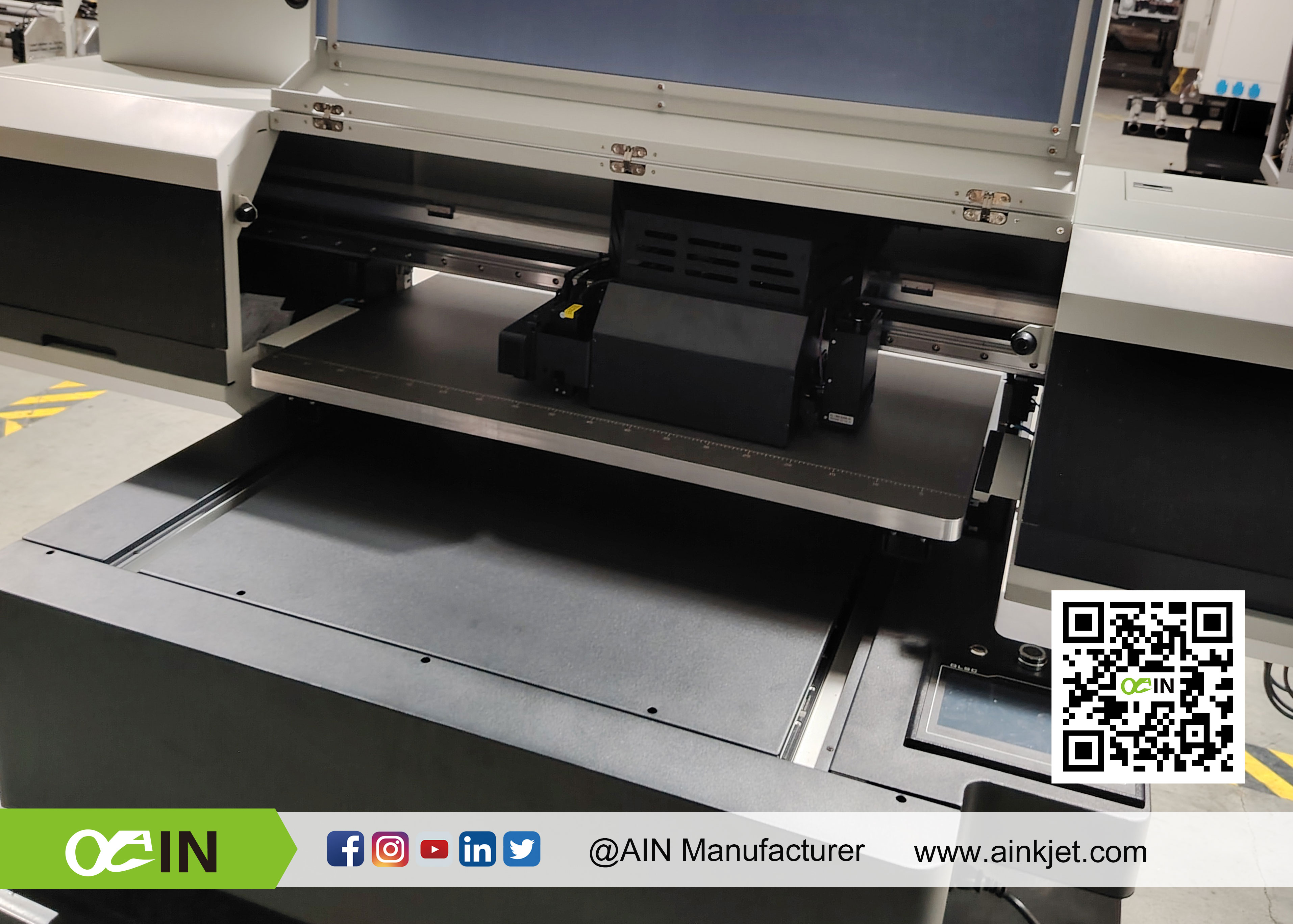

| Digital UV flatbed Printer Al Visual Positioning CCD Visual Positioning No manual alignment needed. Items can be placed freely in the printing area. Saves time and boosts efficiency, revolutionizing traditional processes like silk-screening, spray-painting, and decal application. More eco-friendly, cost-reducing, and simplifies production. 2.5D Texture UV Flatbed Printing Solution The 2.5D texture UV flatbed printing solution, leveraging its advantages of three dimensional effects, multi - material adaptability, and flexible craftsmanship, is widely applied in fields such as signage, packaging, and decoration. Wide adaptability Supports covering high-precision signage, customized printing of flatbed products on multiple materials, 3D effect printing of label films, and packaging printing for cylindrical containers. They adapt to diverse material and creative needs. Upgrade stability Upgraded flatbed structure, multiple printing modes, AI visual scanning, etc., paired with an intelligent component system, enabling efficient, precise, stable and intelligent operation. |

|  |  |  |

|  |  |  |

New Feature of UV Printer We have an excellent technical team, which can be designed according to customers requirements. |

CCD Visual Positioning Unlike ordinary flatbed UV printers, it doesn’t require manual alignment. Users can place items randomly on the printing area, which saves a substantial amount of time and boosts efficiency. This feature revolutionizes traditional processes such as silk - screening, spray - painting, and decal application. It is more environmentally friendly, reduces costs, and simplifies the production process.

| |

2.5D Texture UV Flatbed Printing Solution Rich Three-Dimensional Effect: The UV flatbed printing technology combined with 2.5D texture cansimulate various tactile and visual textures (such as leather grain, fabric, natural stone, etc.), makingthe pattern more layered and three-dimensional. Compared to traditional two-dimensional printing,it significantly enhances the sense of reality and visual impact. Multi-Material Adaptability: lt can directly print on materials such as metal, glass, ceramics, wood.and plastic, expanding design freedom. Craft Flexibility: Supports a variety of post-processing techniques such as matte, glossy, embossing,and hot stamping, enabling customized combinations to achieve unique artistic effects. 2.5D texture UV flatbed technology stands out for its high precision, multi-material adaptability, andrich tactile effects, widely used in Braile and Signage、 Luxury Packaging and Labels、Custom ProductPersonalization、Interior Décor and Art Reproduction、Prototypes and Branding Samples ect.

|

Printer Heads

Epson i1600-U1 Print Head

PrecisionCore Technology a. MEMS manufacturing and thin film piezo element can realize high precision and high density (600 npi/2 rows of nozzles). Contributes to compact, high speed, high quality, and high image quality. b. Precision made of Epson unique MEMS nozzles and an ink flow path ensure the perfectly round ink droplets are placed accurately and consistently. Epson i1600-U1 UV is a cost-effective 1.33inch-wide MEMs head series providing high productivity and high image quality with 600dpi high-density resolution. This printhead is suitable for UV inks. It is unlocked.

| Model | I1600-U1 / I3200 optional | |

| Compatible ink | UV Ink | |

| Dimensions(WidthxDepthx Height) | 69.1mm x 59.4mm x 35.6mm | |

| Weight(g) | 60 | |

| Nozzle Numbers | 1600 | |

| Length Between Nozzles(inch) | 1/300 | |

| Nozzle Row | 4 rows | |

| Max color/head | 4 colors | |

| Resolution | 300dpi/row, 600dpi/2row | |

| Effective Printing Width(mm) | 33.8 | |

| Droplet ejection performance(kHz) | Binary | 5 pl(43.2kHz) |

| 3 levels grey scale | 6,12.5 pl(21.6kHz) | |

| 4 levels grey scale | 3.8,6.2,9.3 pl(21.6kHz) | |

| Viscosity range(mPa.s) | 5-7 mPa・s | |

Features

|

|  |  |

| Intelligent maintenance components Automatic moisturizing and cleaning components,equipped with automatic moisturizing function for he printheads, support regular cleaning, can reduce the risk of heads clogging and ensure continuous and stable operation of the equipment. | Independent flash spray slot structure Automatic flash spray before printing can better improve the speed and accuracy of printing, and the independent design structure is more convenient. | Stable and long-lasting ink supply system Combined with siphon continuous ink supply, positive pressure ink damper and white ink timed stirring function, it can reduce ink blockage and long-lasting output. With the ink shortage alarm function, it can monitor the ink supply situation in real time | Strong and stable integrated frame structure The high-strength integrated material structure makes the overall performance more stable and provides long-term and stable output. The full-coverage mask not only improves operational safety, but also reduces dust adhesion during printing, ensuring high-quality printing output. |

Application

Applications of AI Visual Positioning Digital inkjet UV flatbed Printer

High-precision badge and sign application

Award coins and medals: can accurately position and print on metal award coins and medals, ensuringprinting quality and detail.

With the help of visual positioning, the text and pattern can be accuratelypositioned.lt supports a variety of materials such as metal,

PVC, acrylic, etc., and can meet the needsof diferent scenarios such as industrial logos, commercial signs, and personalized badges.

Customized applications for flatbed products etc

Most materials can be printed: plastic, glass, ceramics, paper, paperboard, metal, leather and so on.Such as pen, notebook, phone case,

mouse,vase, bottle, can, mug, packing box, purse,pad, USB flash disk, electric appliance, suitcase, key ring and other different size products.

Application of label film (UV DTF)

The combination of UV printing and DTF technology can create a 3D effect on the printed images, addinga sense of depth and texture.

Wide Application Range:UVDTF Crystal Labels can be applied to a variety of hard, smooth surfaces, such as glass, metal, acrylic, wood, plastic, ceramic, and more.

Application of cylindrical

Cylindrical digital printing is widely used in the packaging industry for printing on cylindrical containers,such as bottles,

cans, and tubes.This allows for the creation of eye-catching and informative packaging that enhances product appeal.

Standard cylindrical printing mold :easily cope with the printing needs of various shapes to meet diversifed creativity.

Technical Specifications

| AJ-9060X4 AI Visual Positioning Digital Inkjet Uv flatbed Printer | ||||

| Model | AJ-9060X3 UV | AJ-9060X4 UV | AJ-9060X4 UV | |

Print Head | Type | EPSON I1600-U1*1(W) EPSON I3200-U1HD*1(C) EPSON I1600-U1*1(V) | EPSON I1600-U1*2(W) EPSON I3200-U1HD*1(C) EPSON 11600-U1*1(V | EPSON I1600-U1*1(W) EPSONI3200U1HD*1(C) EPSON I1600-U1*1(V) EPSON I1600-U1*1(Pr) |

| Quantity | 3PCS | 4PCS | 4PCS | |

| Ink dot size | 3.5pl | |||

| Print speed | Finish printing an A2 sheet in 3 mins | |||

Ink | Type | LED UV | ||

Color | W, color and V are all availableCoating, W, color, V all availableColor, W, color, V are all available | |||

| Ink supply method | Syphon ink supply | |||

| Printing Size | 900*600mm | |||

| Positioning System | CIS Linear Camera | |||

| Moisturizing Structure | Fully automatic lifting moisturizing component | |||

| RIP Soft | Support Riin, Maintop6.0, photoprint, ONYX and other software | |||

Computer Configuration | operatina System | Windows11 | ||

Hardware Requirements | CPU: Intel Core i9-12900K (boxed to ensure quality) Motherboard: brand motherboard (Gigabyte, Asus, etc.) Memory: Kingston)128GB DDR43600(32G*4) Hard disk: 1TB solid state drive M.2 NVMe 3500MB/s6 | |||

| Transmission Interface | Network Port | |||

| Power Requirements | Input Voltage | 220V+5 %,16A,50Hz +1 | ||

Optional Components | Cylinder Components | |||

| Machine Dimensions | 2048*1290*1006 | |||

Machine Weight | Rack Weight : 2250*1550*1122 Packaging Weight : Gross weight 356.5Kg / Net weight: 201.5Kg | |||