Views: 0 Author: Site Editor Publish Time: 2025-09-22 Origin: Site

With the growing demand for high-quality, efficient printing in the advertising and decoration industries, UV fluorescent inkjet printing technology has emerged as a powerful solution. This technology offers superior durability, fast printing speeds, and vibrant colors, making it ideal for creative applications. In this article, we will explore the working principle of UV fluorescent printing technology and its advantages over traditional fluorescent printing.

UV inkjet printing works by using nozzles to spray UV ink onto the substrate, which is immediately cured by ultraviolet light. This rapid curing process ensures the ink adheres quickly to the surface, resulting in high-quality, long-lasting prints.

Fluorescent Effect Generation

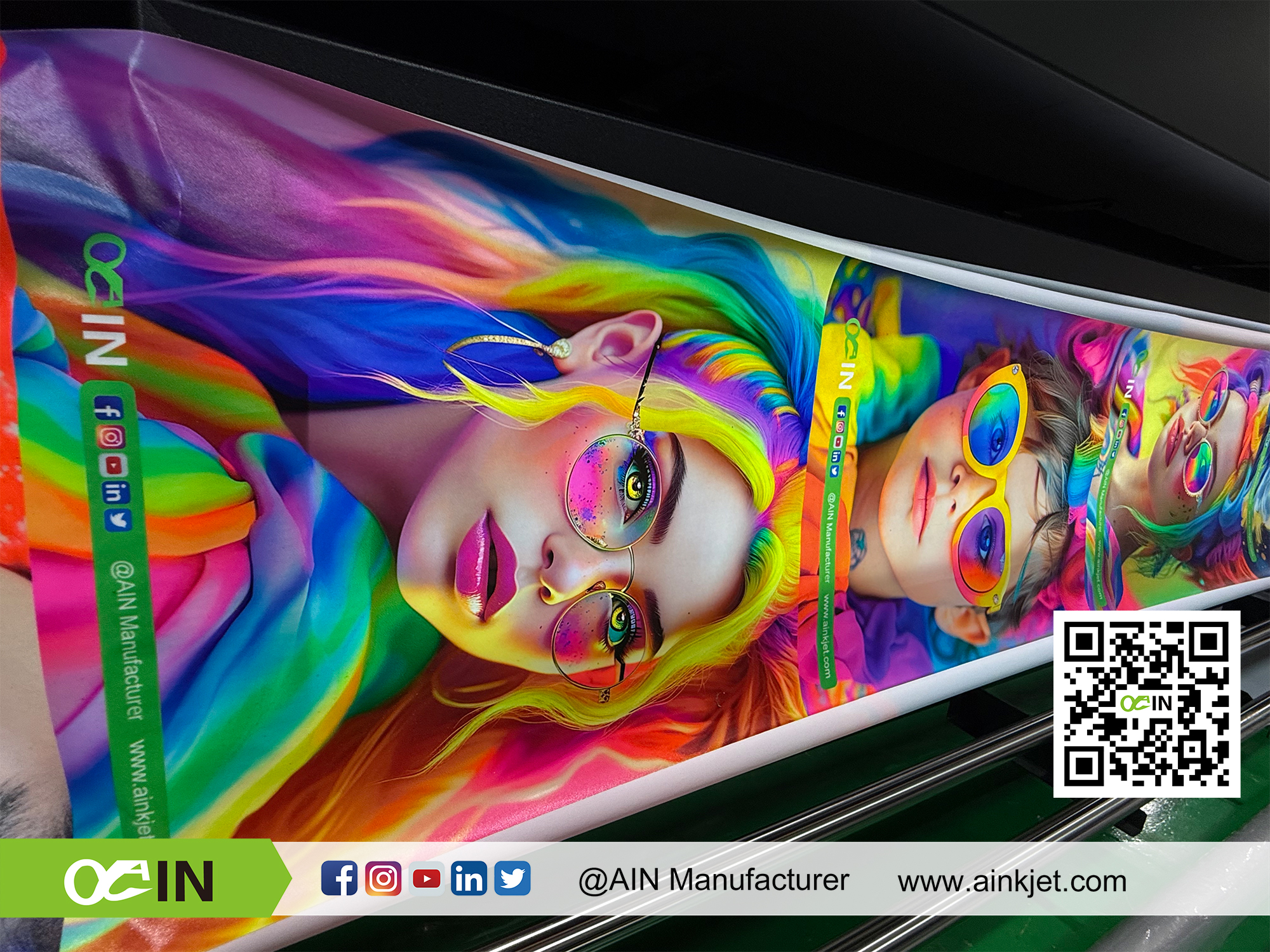

UV fluorescent ink contains special fluorescent pigments that glow under UV light, providing stunning visual effects. During the day, the fluorescent ink shows bright colors, while at night it emits a glowing effect, making it highly appealing for creative applications.

|  |

Working Principle

The printhead uses precise nozzles to evenly spray ink onto the substrate. Once the ink is deposited, it is immediately cured by UV light, ensuring that the image remains sharp and vibrant. This rapid curing process sets UV fluorescent printing apart from traditional inkjet printing, offering both efficiency and high quality.

|  |  |

Traditional Fluorescent Printers: These printers typically use water-based or solvent inks, which require longer drying times. The inks can also be affected by humidity or temperature changes, and they tend to fade over time, reducing their durability.

UV Fluorescent Printers: UV printers use UV-cured inks that dry instantly under UV light, solving the slow drying issue of traditional inks. UV inks are more durable, offering longer-lasting fluorescence and resistance to fading.

Traditional Fluorescent Printers: These printers usually have lower printing accuracy and slower speeds. Ink penetration and paper deformation can occur, leading to inconsistent results, especially with large print jobs.

UV Fluorescent Printers: UV printers offer higher resolution (up to 2400dpi) and faster printing speeds, providing precise, vibrant prints and greater efficiency for large-scale printing.

Traditional Fluorescent Printers: These printers are typically limited to flexible materials like paper and fabric. They struggle with hard materials such as plastic, metal, or glass, resulting in poor print quality.

UV Fluorescent Printers: UV printers can print on a wide variety of materials, including plastics, metals, glass, and wood, making them versatile for applications such as signage, displays, and customized products.

Traditional Fluorescent Printers: Solvent inks can release harmful gases during printing, impacting the environment. Water-based inks, while more eco-friendly, have slower drying times and higher energy consumption.

UV Fluorescent Printers: UV inks do not contain volatile organic compounds (VOCs), making them more environmentally friendly. Their fast curing process also improves energy efficiency by reducing drying time.

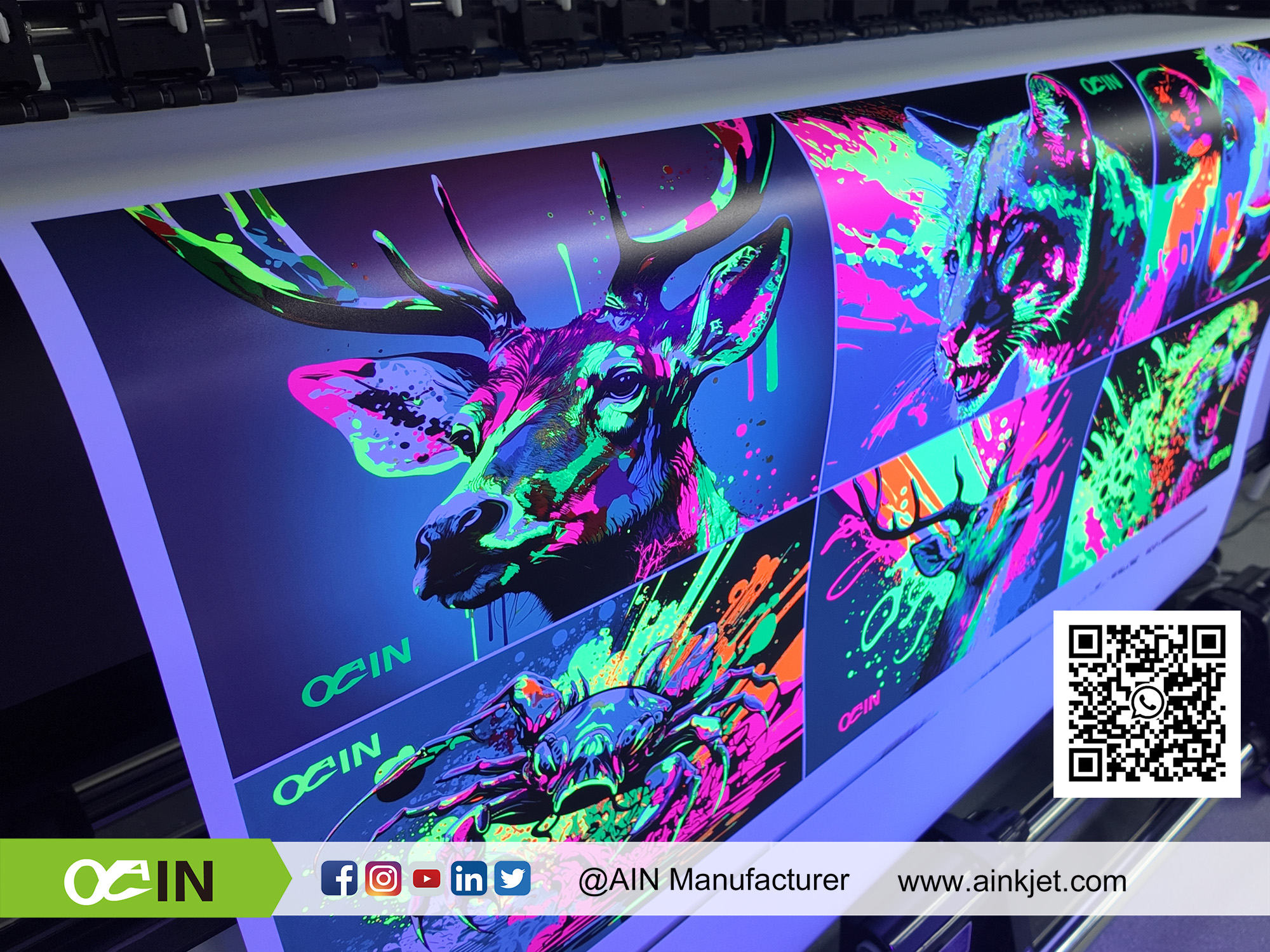

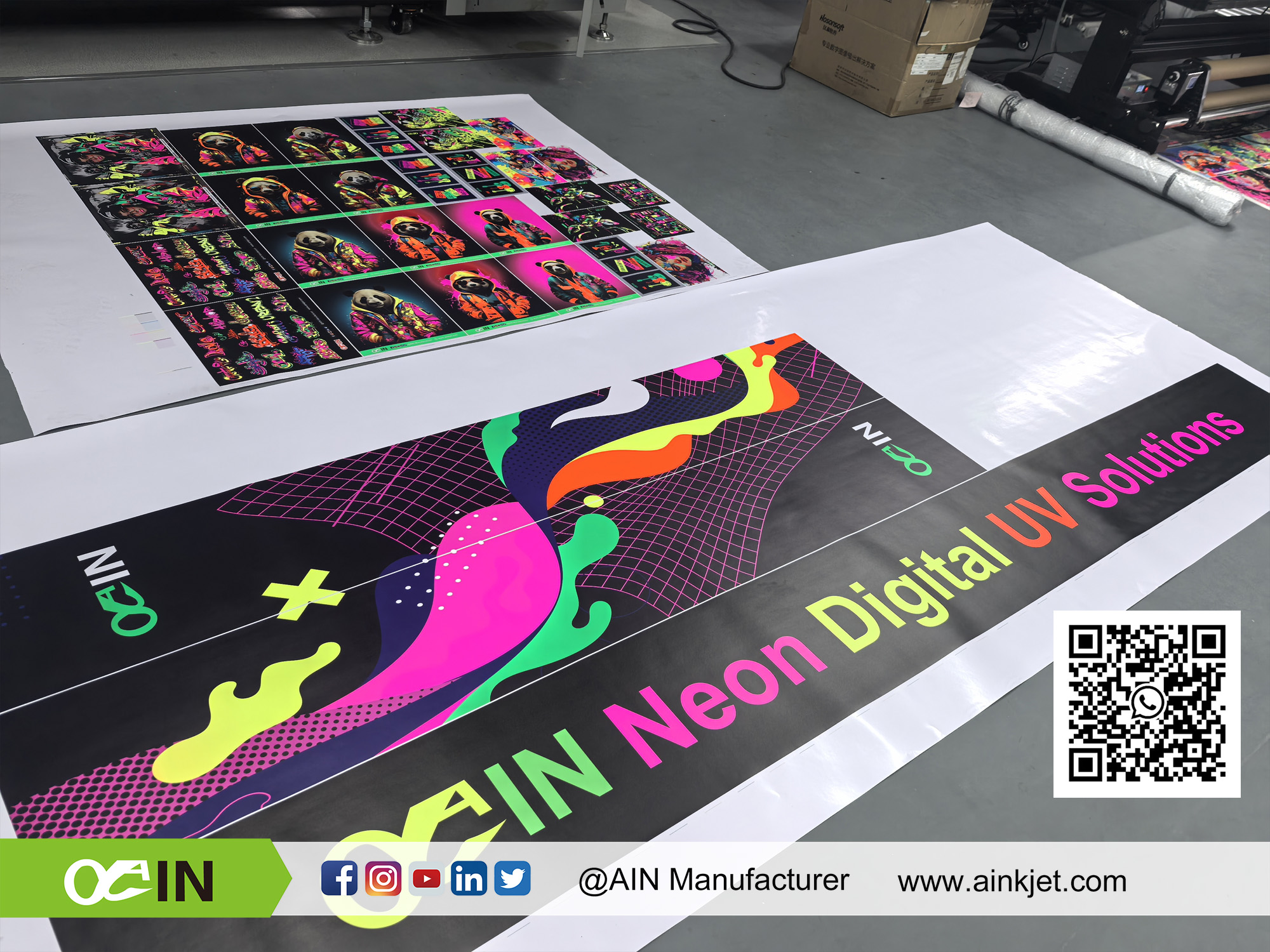

Roll-to-roll printing combines the advantages of fluorescent technology to significantly improve production efficiency. By utilizing UV fluorescent inkjet printing technology, large-scale production can be achieved while reducing production costs. The fluorescent effect greatly enhances the visual impact of advertisements, further personalizing brand imagery.

The AJ-1902UV printer features two EPSON i3200/i1600 printheads (optional), an upgraded frame, wider printing coverage, and more stable output. Its stability and versatility allow for efficient production across various materials. Additionally, the ink bottle alarm system and safety features ensure reliable and safe operation

From dynamic mobile advertising to static scene creation, from mass-market product packaging to premium cultural and creative customization, the AJ-1902UV printer's applications span every facet of commercial promotion and creative execution. Its “print-on-anything” material adaptability and “strikingly vibrant” color performance serve as the brand's key weapons for standing out in all-scenario marketing.

Mobile Trends & Outdoor Advertising

Creative Vehicle Decals & Wraps

Transcending conventional decals, high-precision patterns are printed directly onto vehicle bodies or specialized films. Enhanced with fluorescent colors, these promotional vehicles become moving landscapes day and night.

Creative Advertising Posters & Laser-Effect Posters

Direct printing on flexible materials combines laser finishes with fluorescent inks to create metallic textures and neon-like effects, making flat advertisements “pop” off the page.

Scenario Experiences & Atmosphere Creation

Atmospheric Scene Lightboxes

Print intricate images on translucent materials. Fluorescent inks glow brighter through light, creating layered luminous effects to build thematic ambiance effortlessly.

Holiday Atmosphere Cards/Tickets

Customize exclusive tickets and greeting cards. Spot fluorescent UV printing + textured finishes elevate tactile quality and ceremonial feel, adding collectible value.

Product Packaging & Personalized Customization

Custom Labels & Product Packaging/Bottle Stickers

Print graphics and QR codes directly onto diverse materials without plates. Fluorescent colors boost shelf visibility, while strong adhesion ensures lasting durability.

Cultural & Creative Craft Cards/Personalized Greeting Cards

Achieve fluorescent effects on specialty paper, wood, plastic, and other materials. Infuse handcrafted warmth to transform creative concepts into tangible products rapidly.

Special Decorations & Display Solutions

Display Decorative Stickers/Soft Packaging Stickers

Adheres to soft materials like leather, wood, and rubber. Empowers mall aesthetic displays and electronic device protective films, expanding possibilities for retail decoration and personalized customization.

Contact AIN to learn more about this creative printing solution!

|  |

|  |