| Availability: | |

|---|---|

| PDF Export | |

Printer Informations

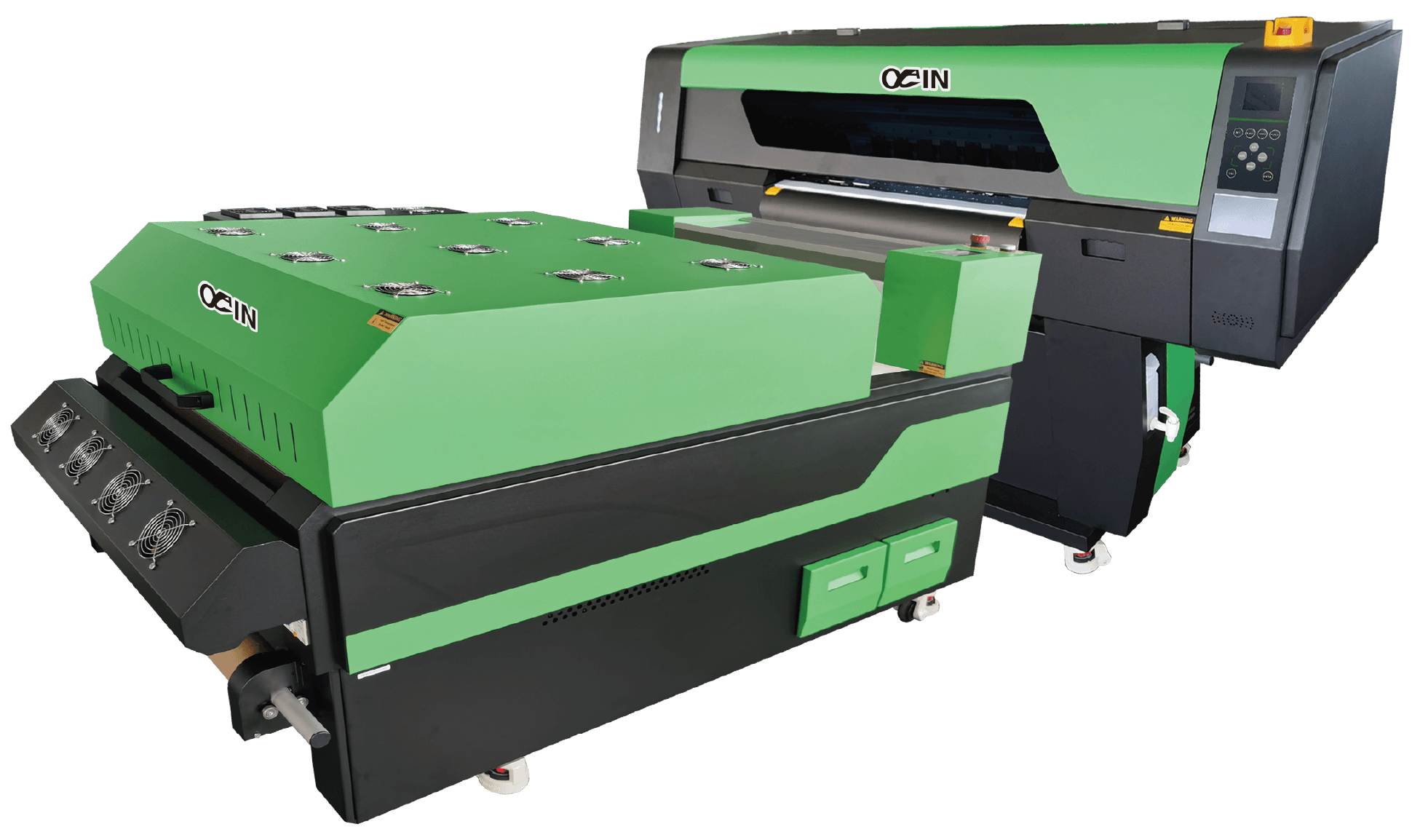

| HIGH VOLUME DTF PRINTING One-Stop AIN DTF MAX Printing Solution Offers one-stop DTF printing, supporting fluorescent/gradient colors & special PET film printing. Integrates printing, powdering and curing in one production line for integrated operation. Stable & Reliable Operation Simple startup (ready after ink loading/debugging), accurate stable feeding, guaranteed printhead/ink condition & printing effect. Enables intelligent control, quiet energy-saving, real-time monitoring, stable performance and cost saving. High Printing Precision Optional 2-6 i3200-A1 printheads (adapts to needs/output), supports multi-precision modes, meets diverse requirements & efficiently finishes large-batch T-shirt printing. Rich Ink Colors Uses AIN DTF inks (bright colors, high fastness) for various fabrics/materials, satisfying personalized T-shirt designs with high color demands. Wide Application Range Suitable for making fashion items (T-shirts, hats, backpacks, lanyards, shoes) and applicable to denim, non-woven bags, gift bags, pearl clothing, baseball caps, fabric gift boxes, etc. to enhance outfit personalization. |

New Feature of DTF Printer We have an excellent technical team, which can be designed according to customers requirements. | |

| AIN DTF GOAL: - Make it affordable to anybody within the printing industry - Create compact and reliable DTF printing solution - Reduce amortization time to a minimum - Fast installation and easy to use - Customer satisfaction

New PDF Powder Shaker ☑ Appearance upgrade ☑Drying tunnel extensio ☑Power optimization ☑Color screen control interface |

| HIGH VOLUME DTF PRINTING SOLUTION AINKJET DTF is carefully designed to reduce maintenance to a minimum. With popular RIPsoftware each print will be produced in a quality way beyond any competition, but still ainkjet dtf every aspect of the print will be optimized in order to make it cost effective. WIDE RANGE OF PRINTING SUPPLIES AIN DTF supports wide range of printing supplies All AIN DTF supplies are certi cated with CE -Various types of powders (white and black) -Various types of DTF films (dazzling film/warm film/luminous film/single side film/double side films) | AINKJET UV DTF INKS All our DTF inks are specially developed and test to ensure vivid colors and maximum fastness -Highest health standards -Vivid colors Regular color Transition color Fluorescent color

|

|  |  |  |

|  |  |  |

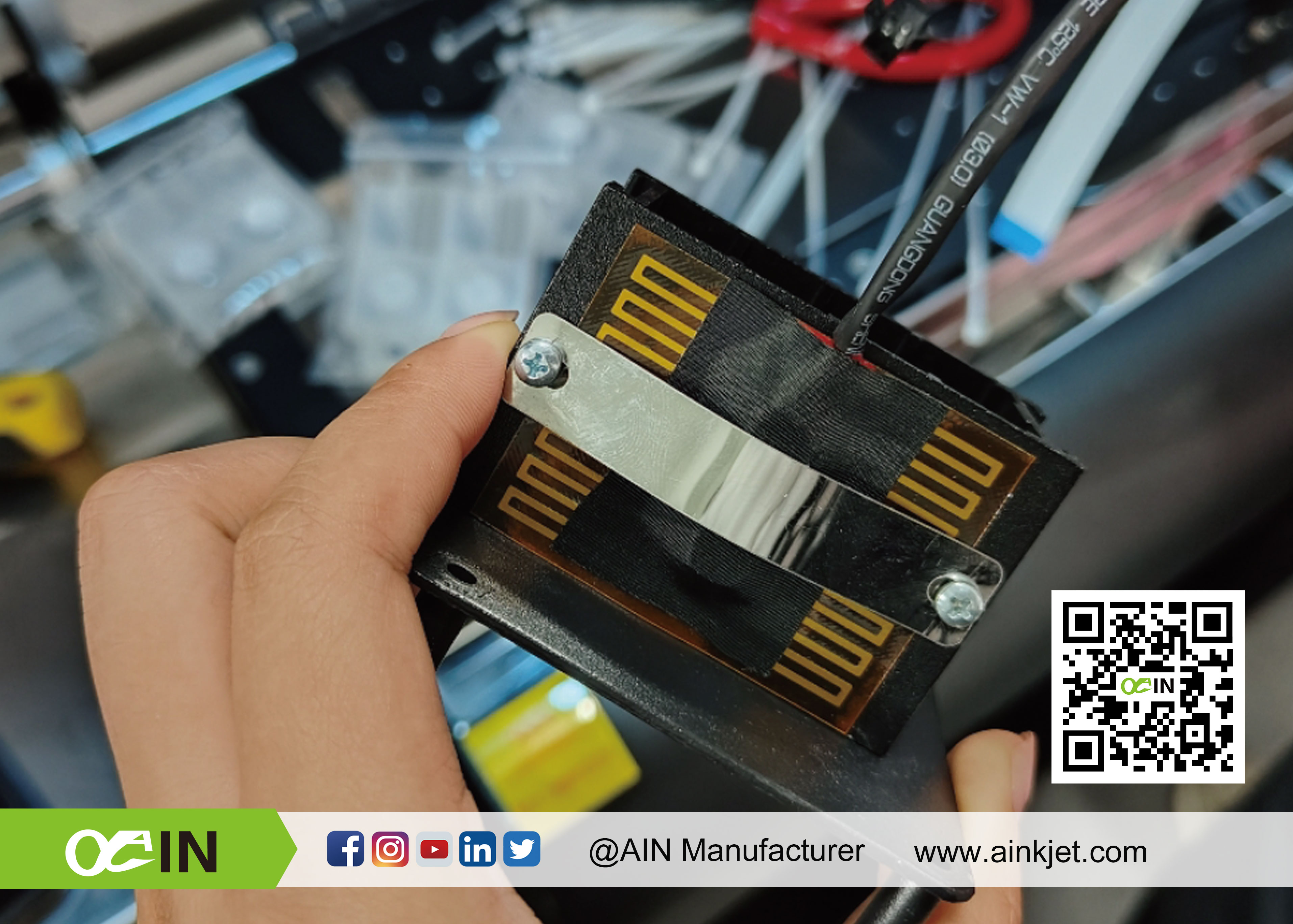

Printer Heads

| Epson Inkjet Head - i3200-A1 The Epson authorized iI3200-A1 Water is a cost-effective 1.33inch-wide MEMs head series providing high productivity and high image quality with (600 dpi/colour) high-density resolution. This printhead is suitable for water based inks. Ink ejection of up to 4 colours realize with high resolution .PrecisionCore print head has proven high durability and extended service life by Epson's industrial printers

| Product name | EPSON i3200-A1 |

| Ink Type | Aqueous | |

| Type | PrecisionCore MicroTFP printhead | |

| WidthxDepthxHeight | 69.1x 59.4 x 35.6 mm | |

| Number of Nozzle | 3200 | |

| Nozzle pitch/nozzle row | 1/300 inch | |

| Nozzle rows | 8 rows | |

| Nozzle Resolution | 300 npi /row 600 npi/2 rows | |

| Max. number of colour inks | 4 colours | |

| Droplet volumes | 6 pl (Single mode) | |

| 6.3,1 2.3 pl (Multi mode) |

Technical Specifications

| T-shirt Digital Heat Transfer Printing Machine | |||

|---|---|---|---|

| Model | AJ-620 DTF MAX Power Shaker | ||

| Print Head | 2/3/4/5/6 Print Heads | ||

| Printing Technology | Piezoelectric Inkjet | ||

| Acceptable Media | Width | 620(mm) | |

| Thickness | Maximum 39 mil(1 mm) | ||

| Printing Width | 600 mm | ||

| Ink Cartridges | Type | Transfer Pigment Ink | |

| Color | 2/4/5 Heads - 5 Colors , 3/6 Heads - 9 Colors CMYK / LcLm / R G B O / Fluorescent Colors Optional+W | ||

| Applicable Medium | Transfer film | ||

| Color Manage | ICC or density curve | ||

| Media Heating System | Powder & color fixing machine | ||

| Interface | 2/3/4 Heads : RJ-45/LAN 5/6 Heads : USB | ||

| RIP Software | Main top & PhotoPrint | ||

| Power supply | 50HZ/60HZ,220V/110V/10A | ||

| Environment | Temperature | 20℃ to 28℃ | |

| Humidity | 65% to 75% | ||

| Printer Dimensions(With Stand) | L1958mm*W835mm*H1420mm | ||

| Packing Dimensions | L2005mm*W990mm*H1350mm | ||

| Packing Weight | 300kg | ||

| Media Width | 0-600mm | |

| Applicable Medium | Nylon, Chemical Fiber, Cotton, Leather, Swimwear, Wetsuit, PVC, EVA, etc. | |

| Powder Control | Powder shake control, powder control, powder direction and volume control | |

| Heating & Drying Function | Multi-stage heating system, drying, cold air fan function | |

| Rewind Function | Automatic induction winding | |

| Electrical Parameters | Rated Voltage: 220V | Rated power supply: 30A |

| Rated power: 6.6KW | Power Consumption: 2.2 KWh~5KWh | |

| Machine Size/Weight | 1900* 1120* 1180mm G.W. 235kg N.W.210kg | |

| Packing Size/Weight | 1780*980*1040mm / 1780*1100*1040mm(Built-in smoke filter) | |

Features

| Heads installation-free After you receive the printer , there is no necessary to install the print heads . After installing the ink and simple debugging , it can be printed directly |  | Tension bar media feeding system The intelligent tension bar film feeding system makes feeding more accurate and stable . |

| Automatically moisturize online Special board control configuration,To prevent the ink from clogging the heads, moisturizer at regular intervals to keep the heads clean and moist . Online humidification system , which can keep the best working condition of the . |  | Electric pinch roller control systems The electric control pinch roll, the PET film evenly stressed, feeding more accurate, one-button easy operation . |

| Upgraded Damper Heating Independentcontrol switch, heating on all sidestomaintain nozzle status, improve ink fluency.stable output. |  | THK mute guide & Upgraded Pinch Roller Imported high quality THK guide . Highly stable printing with low noise and with longer life ,the first choice for high-end inkjet printers .Electric push rod replaces gear set, more stable paper feeding method. |

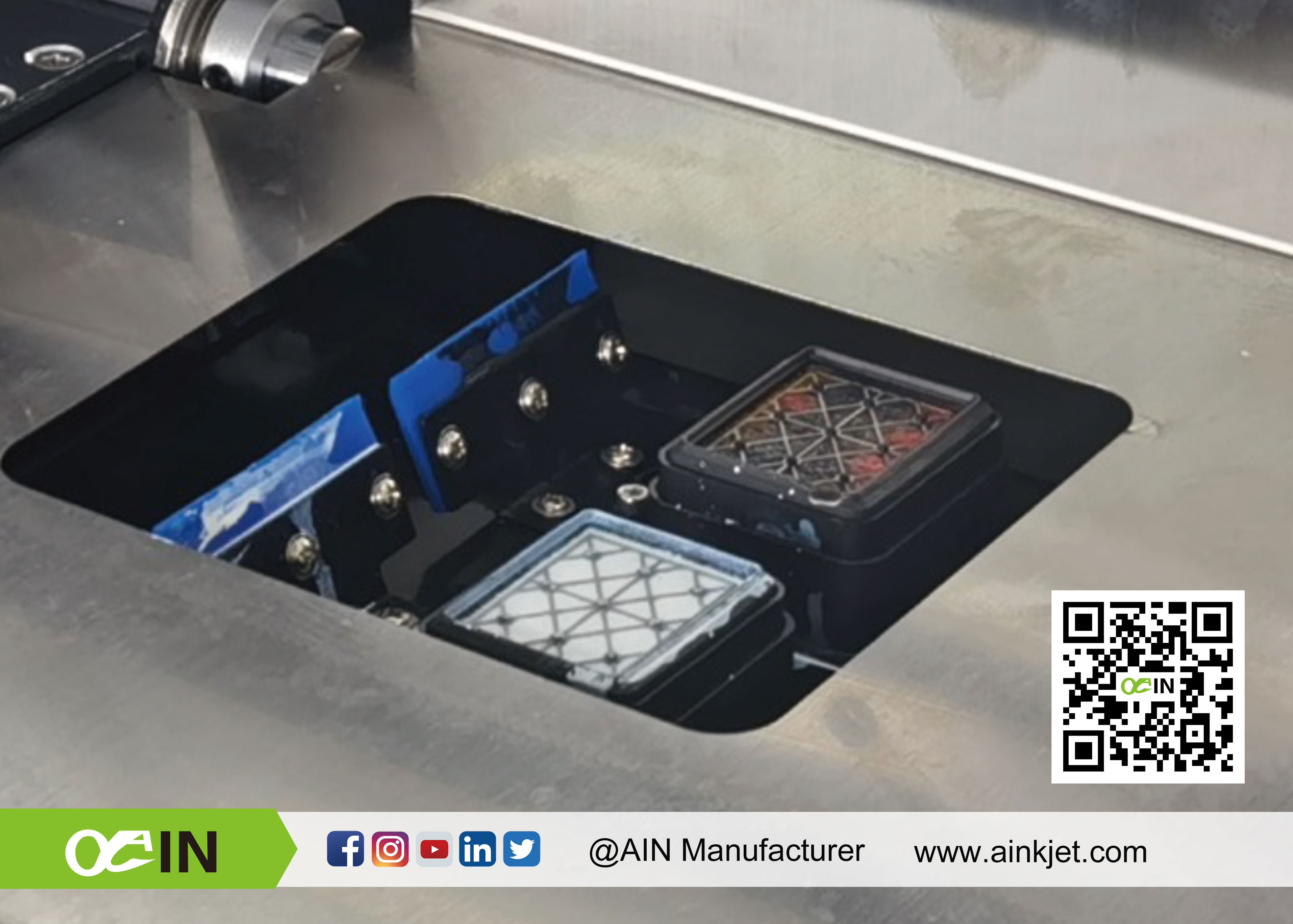

| Nozzle broken hole compensation technologyThe printer can automatically monitor the printing process during the printing process, and will compensate if there is an problem of printing leakage to ensure the perfect output . |  | Powder Control System Better control the precise amount of powder,avoid unnecessary waste, reduce the number of powder return & powder pouring, reduce manual operation costs . |

| LCD Touch Screen Upgraded LCD touch screen, intelligent integrated control. |  | Three-color Light Waste Ink Alarm Upgraded three-color light waste ink alarm, real-time detection of equipment working status. |

Application

Applications of DTF Printer

Commonly used products such as T-shirts, hats, backpacks, lanyards,shoes and more to create unique fashion pieces. It can also be used in denim clothes, non-woven bags, gift bags, pearl clothing,baseball caps, fabric gift boxes, etc. Make your travel outfit unique .

| ● T-shirt ● Canvas ● Backpacks ● Shoes ● Baseball Caps | ● Denim/Jean ● Hoodies ● Gift Bags ● Fabric Gift Boxe ● Sweaters and more...... |