| Availability: | |

|---|---|

| PDF Export | |

Printer Informations

| HIGH VOLUME AINKJET DTF SUPER Designed to accommodate the needs of ever growing market DTF one-stop solution printing solution.Fluorescent color / transition color / special application PET films Everything is done in a single production line printing, powdering and curing. THE NEW UPGRADE We continuously improve and upgrade according to customer feedback, AINKJET series is our best rebate for customer feedback. HUMANIZED DESIGN AlNKJE series is created for anyone within the printing industryBe it beginner or expert AlNKJET series will accommodate any needs required by its owner. From super easy startup to the state of the ar RlP software,with AINKJET DTF anyone can create outstanding print jobs with minimal effort. HIGH OUALITY AND FLUORESCENT INK AlNKJET DTF inks are specially developed to ensure vivid colors and maximum fastnesson widle range of fabrics and other materials. Neon series provides additional fluorescent inks. RELIABLEDTF PRINTING SOLUTION Every component in AlNKJET DTF is designed to last -High precision timing components On demand Piezzo print head Durable ink components -Sturdy exterior. |

|   |   |

New Feature of DTF Printer We have an excellent technical team, which can be designed according to customers requirements. | |

| AIN DTF GOAL: - Make it a ordable to anybody within the printing industry - Create compact and reliable DTF printing solution - Reduce amortization time to a minimum - Fast installation and easy to use - Customer satisfaction Intelligent Powder Shaker Machine

- Equipped with two powder storage tanks - Constant temperature of powder box - Powder blocking device - Intelligent powder control system - Intelligent temperature control drying device - Tension bar media take up device - Built-in oil fume lter purie |

| HIGH VOLUME DTF PRINTING SOLUTION AlINKJET DTF is carefully designed to reduce maintenance to a minimum. With popular RlPsoftware each print will be produced in a quality way beyond any competition. but still ainkjet dtf every aspect of the print wil be optimized in order to make it cost effective. WIDE RANGE OF PRINTING SUPPLIES AINKJET DTF supports wide range of printing supplies AlAINKJET DTF supplies are certificated with CE -Various types of powders (white and black) -Various types of DTF flims (dazzling lm/warm lm/luminous lm/single side lm/double side flim) | AINKJET UV DTF INKS All our DTF inks are specially developed and test to ensure vivid colors and maximum fastness -Highest health standards -Vivid colors Regular color Transition color Fluorescent color

|

|  |  |

| Tension take-up, ensure more stable film feedin | White ink shaking device, improve the fluidity of ink | THK high-precision mute rail |

|  |  |

| Stable bulk system ensures amazing printing speed | Automatic moisturizing function to extend the life of the head | White ink circulation improves the fluidity of ink |

| Width: 60CM Powder Shaker (OEM Service Optional) Bulit-in smoke purifier |

|

Two Powder Storage Tanks: Additional configuration of a second powder storage box allows the falling powder to completely fall into the storage box. Two powder storage boxes are used alternately, effectively avoiding waste. |  |

Constant Temperature of Powder Box: There is a temperature sensor under the powder box. When the temperature does not meet the standard,the powder box will automatically heat up, ensuring thatthe powder remains dry and the effect is not affected by the powder.Especially in humid areas in the south, the effect of automatic heating is particularly evident. |  |

Powder Control Syetem: A brand new powder control structure, with added baffles on both sides, allows all falling powder to fall into the powder box, avoiding powder loss,and the design of the baffles can significantly improve the utilization rate of powder. |  |

Intelligent Powder Sensor: When the sensor senses that the weight of the powder on the paper is not enough,the powder box will automatically start spreading powder, ensuring that the printed pattern can fully touch the powder, thus achieving a perfect printing effect. |  |

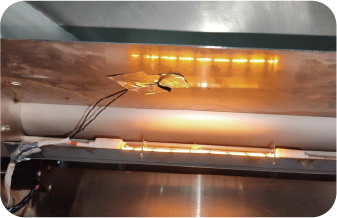

Intelligent Temperature Control: Added the function of heating up and down simultaneously. The new design enables the material to be heated more fully. Thus, the pattern does not deform during film detachment and eliminates the phenomenon of oil return, leaving the pattern in its most perfect state. |  |

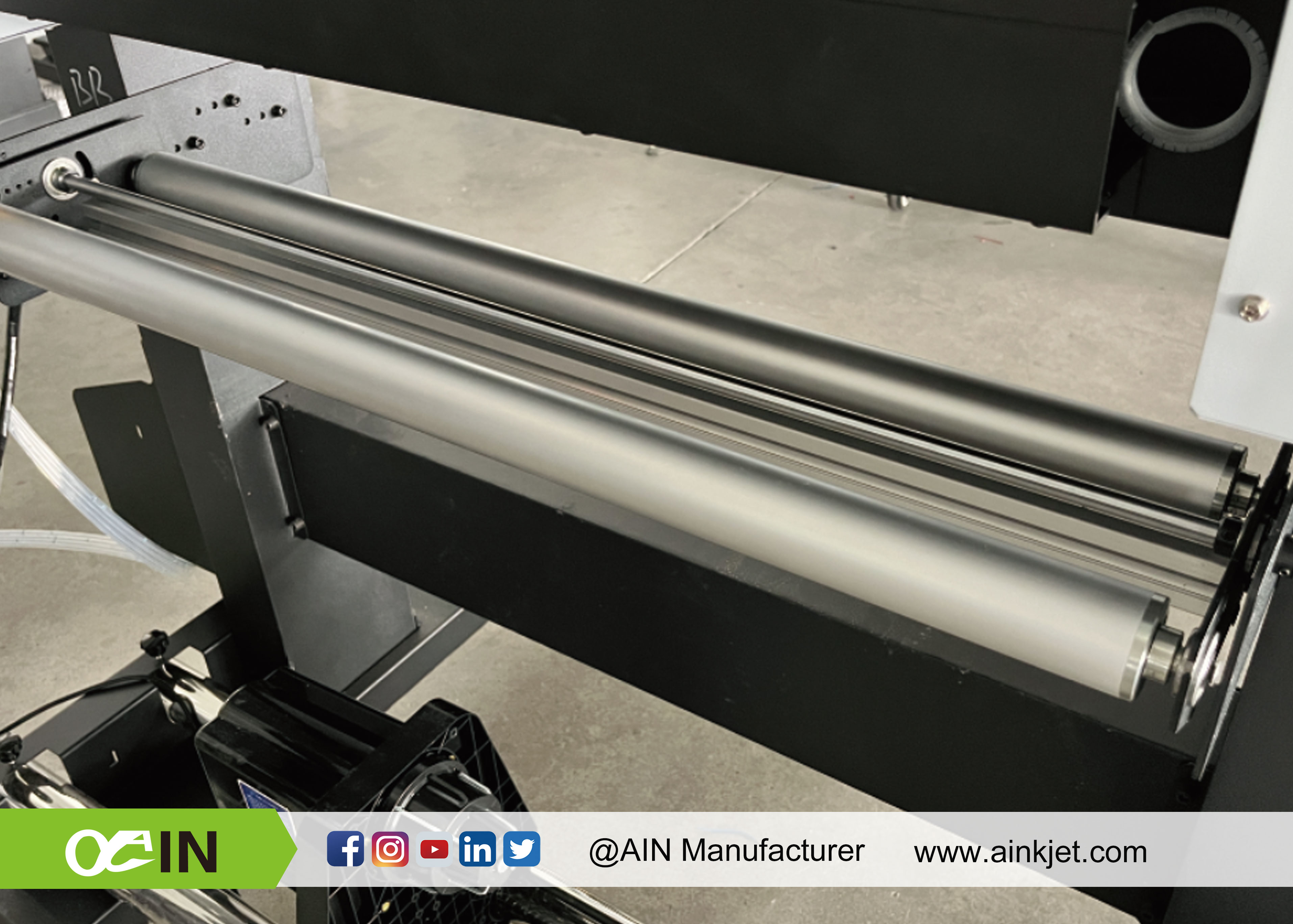

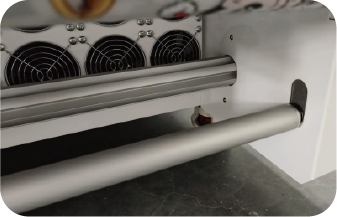

Tension Bar Media Take Up Device: The new machine has added the function of tensionpaper winding, making the winding more neat. |  |

Built-in Oil Fume Filter and Purifier: This new improvement provides customers with the opportunity to choose configurations. The powder shaker equipped with a purifier can automatically remove smoke and powder, which is more convenient and effective in saving workers' operating time and costs. |  |

Printer Heads

| Epson Inkjet Head - i3200-A1 The Epson authorized iI3200-A1 Water is a cost-effective 1.33inch-wide MEMs head series providing high productivity and high image quality with (600 dpi/colour) high-density resolution. This printhead is suitable for water based inks. Ink ejection of up to 4 colours realize with high resolution .PrecisionCore print head has proven high durability and extended service life by Epson's industrial printers

| Product name | EPSON i3200-A1 |

| Ink Type | Aqueous | |

| Type | PrecisionCore MicroTFP printhead | |

| WidthxDepthxHeight | 69.1x 59.4 x 35.6 mm | |

| Number of Nozzle | 3200 | |

| Nozzle pitch/nozzle row | 1/300 inch | |

| Nozzle rows | 8 rows | |

| Nozzle Resolution | 300 npi /row 600 npi/2 rows | |

| Max. number of colour inks | 4 colours | |

| Droplet volumes | 6 pl (Single mode) | |

| 6.3,1 2.3 pl (Multi mode) |

Technical Specifications

| T-shirt Digital Heat Transfer Printing Machine | |||

|---|---|---|---|

| Model | AJ-6203 DTF Super | ||

| Print Head | 3 Print Heads Optional (i3200-A1) | ||

| Printing Technology | Piezoelectric Inkjet | ||

| Acceptable Media | Width | 620(mm) | |

| Thickness | Maximum 39 mil(1 mm) | ||

| Printing Width | 600 mm | ||

| Ink Cartridges | Type | Transfer Pigment Ink | |

| Capacity | Continual Ink Supply System ( 220ML ) | ||

| Color | CMYK+W / CMYKFyFm + W(3H) | ||

| Applicable Medium | Transfer film | ||

| Color Manage | ICC or density curve | ||

| Media Heating System | Powder & color fixing machine | ||

| Interface | RJ-45/LAN | ||

| RIP Software | Main top | ||

| Power supply | 50HZ/60HZ,220V/110V/10A | ||

| Environment | Temperature | 10℃ to 38℃ | |

| Humidity | 40% to 70% | ||

| Printer Dimensions(With Stand) | L1620mm*W620mm*H1590mm | ||

| Packing Dimensions | L1700mm*W750MM*H760mm | ||

| Weight | G.W:230kg N.W:180kg | ||

| Media Width | 0-60CM/0-80CM | |

| Applicable Medium | Nylon, Chemical Fiber, Cotton, Leather, Swimwear, Wetsuit, PVC, EVA, etc. | |

| Powder Control | Powder shake control, powder control, powder direction and volume control | |

| Heating & Drying Function | Multi-stage heating system, drying, cold air fan function | |

| Rewind Function | Automatic induction winding | |

| Electrical Parameters | Rated Voltage: 220V | Rated Current: 30A |

| Rated Power: 6.6KW | Power Consumption: 2.2 KWh~5KWh | |

| Powder Shaker Size | 60cm:1780*980*1040mm | 80cm:1780*1180*1040mm |

60cm:1780*1100*1040mm(Built-in smoke filter) | 80cm:1780*1100*1040mm(Built-in smoke filter) | |

| Packing Size & Weight | 60cm:1900* 1150* 1150mm | 80cm:1900*1350*1150mm |

| 60cm:G.W.235kg N.W.210kg | 80cm:G.W.245kg N.W.220kg | |

Application

Applications of DTF Printer

Commonly used products such as T-shirts , hats , backpacks , lanyards , shoes and more to create unique fashion pieces.It can also be used in denim clothes , non-woven bags , gift bags , pearl clothing , baseball caps , fabric gift boxes , etc. Make your travel outfit unique.

| ● T-shirt ● Canvas ● Backpacks ● Shoes ● Baseball Caps | ● Denim/Jean ● Hoodies ● Gift Bags ● Fabric Gift Boxe ● Sweaters and more...... |

Applications Of DTF Printer | |

T-shirt

Canvas

Backpacks

Shoes

Baseball Caps

Denim/Jean

Hoodies

Gift Bags

Auxiliary Materials

| 6090CT Didital Cutting Machine Suitable for cutting various flexilble materials less than 5mm, such as cardboard, thin plastic,pp backing, rubber cloth, gaskets, imitation leatheradhesive stickers, car stickers, reflective stickers,magnetic stickers, etc. |

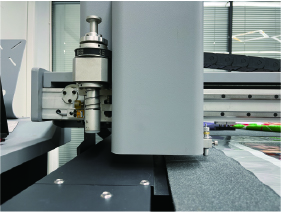

| Machine head: Adopts an independent Z-axismodular design, can combinemany functional tool heads to meetdiverse tasks |  | Working table: Double layer adsorption vacuumtable + gas storage deviceachieve better adsorption capacity. |

| Feeding: Rolling feeding table, automatic feeding and rolling cutting,more efficient operation. |  | Control software: Multi axis control system with independent intellectu aproperty,easy to upgrade and maintain with guarantee. Network interface supports remote upgrades, making transmission more efficient and secure |

| Camera: 5 million pixels industrial camera,with high scanning and positioningaccuracy |  |

Software format: The software can extract images automatically, and supportmultiple formats such as JPG, DXF, PDF, etc |

| Appearance: Designed by professional team,with advanced structure andelegant appearance. |  |

Tools: Machine can combine with various cutting tools such as: oscillating knifedrag knife,half cutting knife, plotter knife,creasing wheel, pen, etc. it is versatileand effective,process and multi materia operations. |

| Model | 6090CT Cutting Machine |

| Working size | 600X900X5mm |

| Feed height | 10mm |

| Tool | Drag kinfe,Plotter kinfe, Creasing wheel |

| Driver | AC Servo |

| Control system | SIGNKEY |

| Camera | 5 million pixels industrial camera |

| Machine structure | Industrial steel pipe box structure |

| Transmission | Z ball screw, XY belt |

| XYZ rail | linear rail |

| Repetitive accuracy | <0.05mm/300mm |

| Maximum no-load speed | 150m/min |

| Max.processing speed | 10~100m/min |

| Repetitive accuracy | <0.05mm/300mm |

| Maximum no-load speed | 150m/min |

| Max. processing speed | 10~100m/min |

| Working table | Double layer adsorption vacuum table+rolling feeding |

| Roll material feed device | Yes |

| Roll material automatic deviation device | Optional |

| Vacuum pump | 1.5KW air cooling |

| Data transmission | Ethernet |

| Instruction format | HPGL or standard G-code |

| Power supply | 220V/50-60HZ |

| Machine size(include material feed device) | 2100*1450*1350mm |

| N/G weight | 500/800KG |

| Optional table size | 1600*2500mm |