Views: 0 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

Transfer Printing: Applications & Trends

Inkjet transfer technology, flexible, efficient, and cost-effective, gains attention in modern printing. Driven by personalized demand and environmental awareness, it expands into clothing, home decor, and advertising.

Tech upgrades push equipment toward high speed, quality, wide format, and intelligence, with higher efficiency, richer colors, and wider material adaptability as key trends.

The AIN sublimation printer series meets the above needs. With innovative technology, it achieves a high level of intelligence and automation, improves production efficiency, and provides flexible customization services.

Choose sublimation printer Equipment Factors

1. Production needs: Match scale, speed, and quality. Select basic models for small-scale production and high-speed, high-configuration ones for large-scale production.

2、Material compatibility: Prioritize equipment with a wide range of adaptability and the ability to handle special and large rolls of media.

3、Cost control: Focus on initial investment and long-term costs.AIN transfer printing has advantages because it does not require plate making and has a low scrap rate.

4、Operation difficulty: tends to be more intelligent and reduces the technical requirements for personnel.

5、Equipment performance and upgrade: focus on intelligence, automation level, and ease of upgrade.

The AIN dye sublimation printer series is an ideal choice for users and can accurately select suitable equipment according to different customer needs.

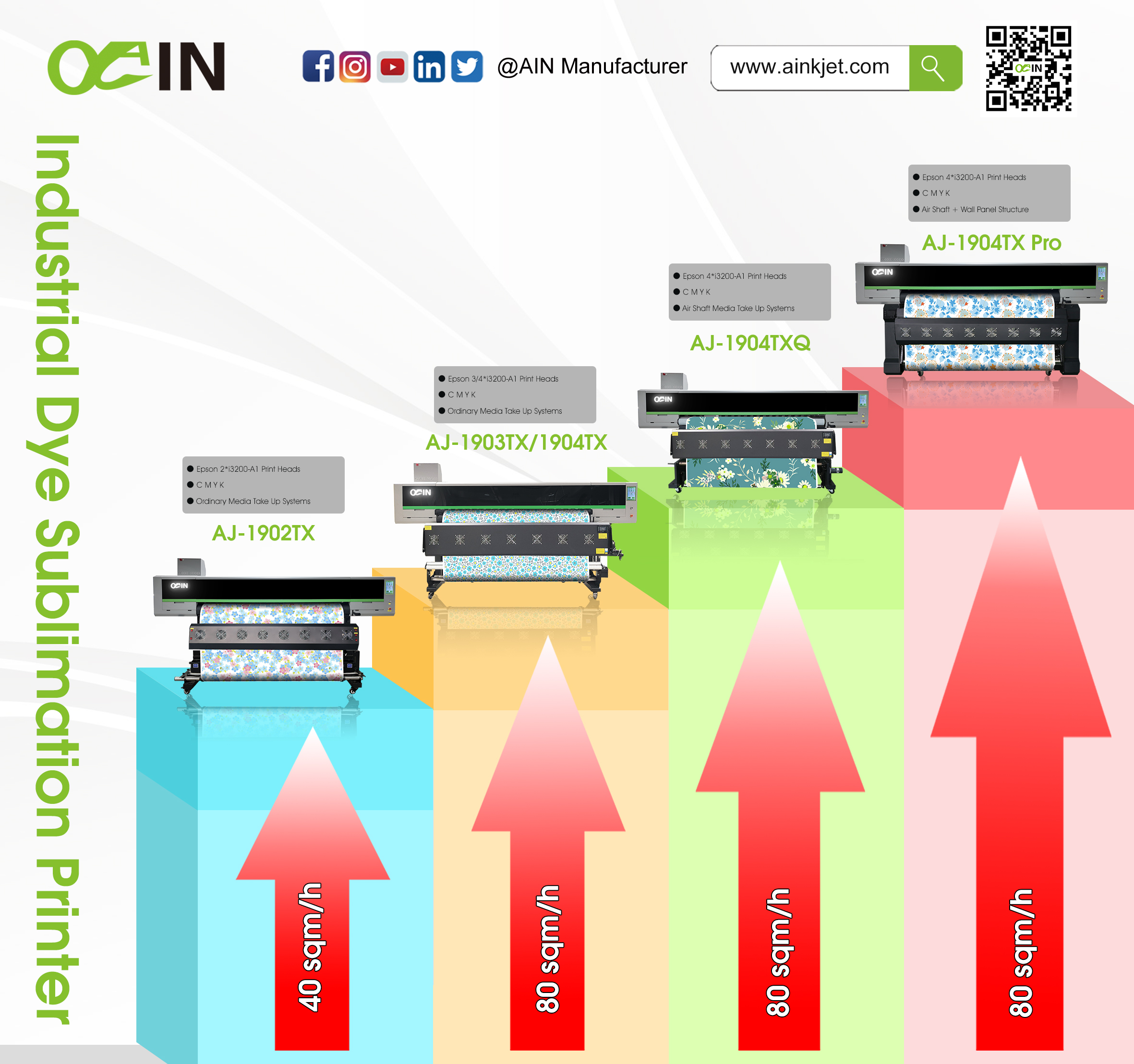

AIN 1.9m width series

This series is designed to meet the diverse needs of enterprises of different sizes.

- AJ-1902TX: Equipped with two Epson i3200-A1 printheads, it supports CMYK color mode and comes standard with a paper delivery mechanism. Its compact size and powerful performance, with a print speed of up to 40 square meters per hour, make it an ideal choice for entry-level users seeking basic printing needs.

- AJ-1903TX/1904TX: Upgraded to three or four Epson i3200-A1 printheads, CMYK color mode, and a standard paper delivery mechanism. Print speeds up to 80 square meters per hour, doubling efficiency and easily supporting business expansion.

- AJ-1904TXQ: Equipped with four Epson i3200-A1 printheads, CMYK color mode, and a standard paper delivery mechanism, it boasts a print speed of 80 square meters per hour, combining speed and quality to easily handle high-end orders.

-AJ-1904TX Pro: This top-of-the-line printer features four Epson i3200-A1 printheads, CMYK color mode, and an aviation-grade optical axis and wallboard structure. Its peak output speed is 80 square meters per hour, and its superior design makes complex printing tasks easy.

AIN high-speed series

This series focuses on providing faster and larger-capacity printing solutions, suitable for large-scale production and high-frequency use scenarios.

- AJ-2008TX PLUS: Equipped with six Epson i3200 A1 printheads, it offers an 8-color configuration (CMYK/CMYK Light Cyan, Light Magenta, Light Black, and Deep Black), a media width of 800-1000 mm, and a print speed of 380 m2/hour. Suitable for printing on soft films and fabrics, it caters to both small and large-scale production, delivering cost-effective and efficient printing.

- AJ-3208TX: Equipped with eight Epson i3200 A1 printheads, it offers an 8-color configuration (CMYK/CMYK Light Cyan, Light Magenta, Light Black, and Deep Black), with optional FY/FM/RE or GR/BL spot colors. It supports media widths of 800-1000 mm and prints at a speed of 500 square meters per hour. It's ideal for large-scale soft film advertising and batch textile printing, meeting the demands for both speed and color diversity.

- AJ-1912TX PLUS: Equipped with 12 Epson i3200 A1 printheads, it offers an 8-color configuration (CMYK/CMYK Light Cyan, Light Magenta, Light Black, and Deep Black), a media width of 1000 mm, and a print speed of 530 m²/hour. Ideal for printing on soft films and textiles, it improves production efficiency for growing businesses.

-AJ-2016TX PLUS: Equipped with 16 Epson i3200 A1 printheads, it features an 8-color configuration (CMYK/CMYK Light Cyan, Light Magenta, Light Black, and Deep Black), a media width of 1000 mm, and a print speed of 600 m2/h. Suitable for large-scale textile and soft film printing.

- AJ-2216TX PLUS: This top-of-the-line model features 16 Epson 13200 A1 printheads, an 8-color configuration (CMYK Light Cyan, Light Magenta, Light Black, and Deep Black), supports 1000mm media and 35g thin paper, has a 300mm guide rail width, and prints at speeds up to 690m²/hour. This ultra-large format printer is an industry benchmark.

AIN transfer VS traditional transfer: Comparison

1. Production efficiency: Traditional transfer involves many steps, requiring screen remaking for image changes—time-consuming and unsuitable for small/multi-batch orders. AIN transfer needs no plate-making; high-speed models just adjust files, greatly shortening cycles.

2. Color performance: Traditional transfer has poor color reproduction, easy deviation, weak layering, and blurred/faded complex patterns. AIN transfer with 8-color configuration and high-precision print heads offers fine transitions, wide gamut, and accurate details.

3. Material compatibility: Traditional transfer has narrow adaptability and conditional restrictions. AIN transfer works with multiple materials, handles special/large-volume media, and expands applications.

4. Cost control: Traditional transfer has a high initial investment, expensive consumables, and high scrap rates. AIN transfer needs no plate-making, with fewer errors, low scrap rates, durable equipment, and better long-term costs.

5. Operation difficulty: Traditional transfer demands high technical skills, with novices prone to mistakes. AIN transfer features intelligent control; staff can operate after simple training.

Choosing transfer equipment requires considering production, material, and cost factors. The AIN sublimation printer series, with diverse models and strengths in intelligence, efficiency, color, and cost, offers high value for businesses. Whether exploring or expanding, AIN delivers comprehensive solutions to seize opportunities in personalized, efficient production.

content is empty!