Views: 0 Author: Site Editor Publish Time: 2025-11-28 Origin: Site

March 10-12, 2026, Guangzhou International Convention and Exhibition Center hosts DPES CHINA 2026 (China International Digital Printing and Signage Exhibition) – the printing/packaging/signage industry’s annual gala. AINJKE, a leading inkjet printing manufacturer, confirms its participation and will present a full line of innovative printing solutions at Booth D04.

The exhibition continues its core 3D silicone TPU printing solution and adds flat/roll-to-roll dual solutions, realizing "flat customization + roll-to-roll mass production" coverage. It delivers all-round tech breakthroughs for sportswear, bag customization, and personalized labels, with multiple star products on show – inviting you to explore new printing industry possibilities!

3D Silicone & TPU Dual Solutions: Customization + Bulk Needs

AINJKET's 3D silicone TPU printing marks its first dual solution for both high-precision customization and mass production, delivering accurate options for diverse production needs.

Option 1: AJ-6090 PRO Flatbed Solution – Small Batch, High Precision, Personalized Needs

Based on the AJ-6090 PRO UV DTF silicone thermal transfer flatbed printer, this device is tailored for high customization, small-batch production, solving the key pain point of "conflict between hard 3D effects and soft fabrics":

•Soft & skin-friendly (no stiffness): AINJKET exclusive UV soft ink + silicone heat transfer film, transferred patterns match fabric softness – no impact on wearing comfort (ideal for sportswear, baby clothes), perfect for high-end brand logos and limited-edition clothing labels;

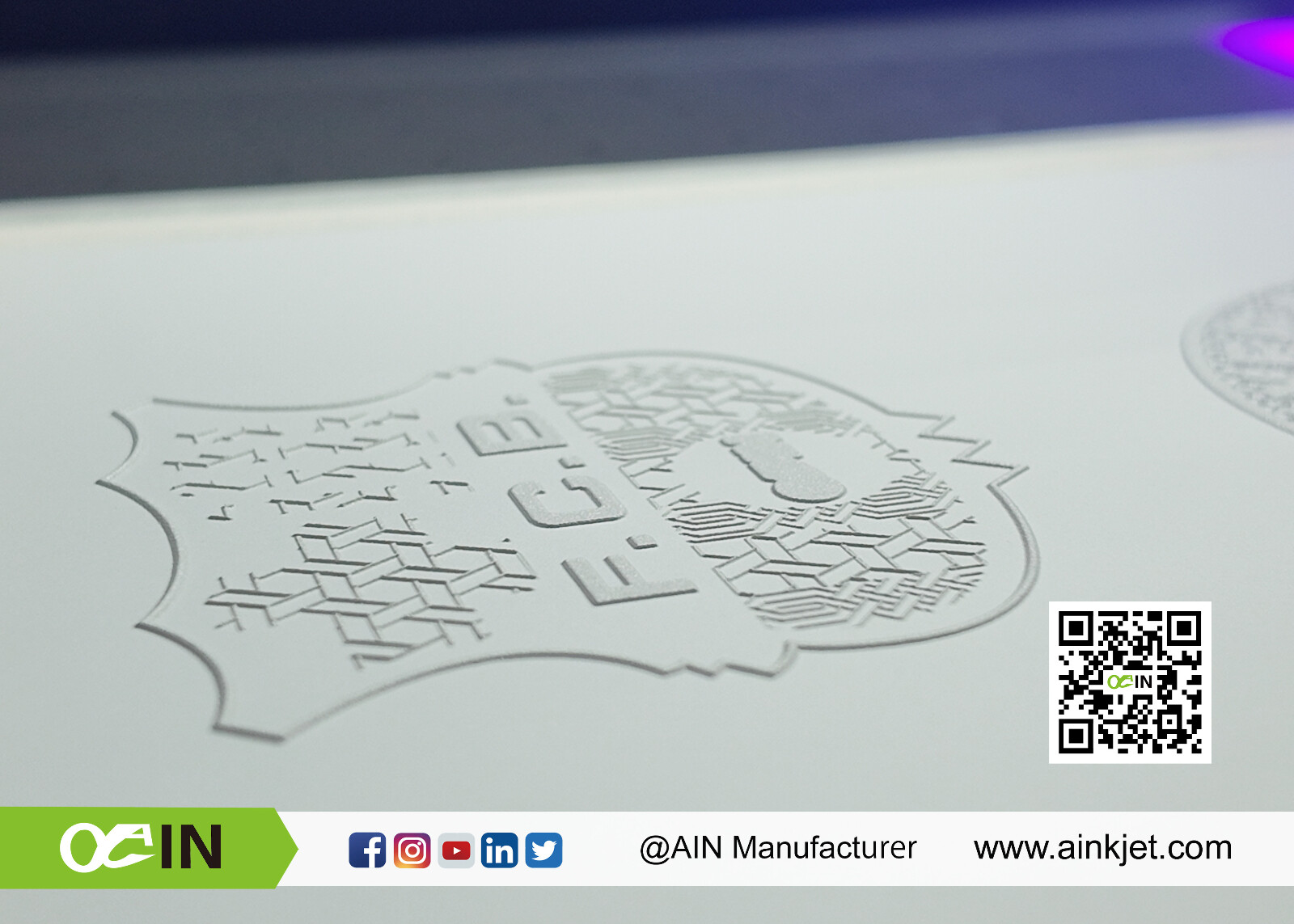

•3D stereoscopic effect: Prints white ink + varnish simultaneously; one-stop "print-cut-heat transfer" process achieves 3D embossment & matte/gloss textures, 3D effect 200% better than traditional flat printing, greatly boosting brand recognition;

•Professional configuration for precision: Optional 2-3 authorized EPSON i1600-U1/i3200-U1 printheads, max 2400dpi; dual UV LED curing + vacuum adsorption platform, pattern consistency error ≤0.1mm in mass production.

|  |  |  |  |

Option 2: AJ-600E PRO Roll-to-Roll Solution – High-Volume, High-Efficiency, Large-Scale Production

AJ-600E PRO 3D Silicone UV DTF Roll-To-Roll Heat Transfer Printer, with core advantages of "continuous production + cost optimization", fills the industry gap in 3D silicone TPU mass production:

•Roll-to-roll continuous production (2x efficiency): Integrates "printing-coating-cutting-heat transfer" with roll-to-roll conveyor (no mid-process material changes); 7㎡/h in 8-pass (720×1200dpi) – 3x faster than traditional flatbed models, ideal for large orders (clothing labels, bag decorative labels);

•Wider material compatibility: UV soft ink + silicone transfer – soft, washable (no fading/deformation after 50 washes); works with cotton/denim/leather/Oxford cloth + plastic/glass/metal, covering sportswear, outdoor gear, electronic casings, etc.;

•Intelligent cost-saving configuration (easy operation/maintenance): 3 EPSON i1600-U1 (4 i3200-U1 optional), CMYK+white+varnish, 600mm width (fits mainstream labels); built-in auto white ink stirring (anti-sedimentation/clogging), full-machine cover (dustproof/safe), synchronous lamination (fewer manual steps); 20% higher powder utilization, ≤1% failure rate;

•3D embroidery-level texture: Layered white ink + varnish for 3D raised effect (max 1.5mm); matte/gloss options – 1/3 the cost of traditional embroidery + richer color gradients, meeting high-end brand needs.

|  |  |  |  |

Full-range star products on show – multi-scenario printing needs covered

In addition to its 3D silicone and TPU dual solutions, AINJKET also offers a portfolio of star products covering three major areas: textile heat transfer, digital labels, and wide-format UV printing, to meet the diverse needs of different industries.

I. Textile Heat Transfer Zone: Multi-mode Coverage – High-Speed Wide-Width, Industrial-Grade Stability, Batch & Desktop Printing

1. AJ-2008TX Plus 2m High-Speed Wide-Width Dye-Sublimation Printer – High Capacity

To meet large-format, high-speed textile printing demands, we overcome capacity bottlenecks with "wide width + high efficiency":

•2m ultra-wide coverage: Fits curtains, outdoor tents, large sportswear fabrics – reduces splicing and enhances finished product appearance;

•Industrial-grade high-speed output: 4 EPSON 13200-A1 printheads, 120㎡/h in CMYK mode – 20% more efficient than conventional models;

•Intelligent stable configuration: Air shaft auto material collection, constant temperature drying, nozzle anti-collision sensor – ensures smooth fabric feeding in mass production, ≤0.5% failure rate after 8h continuous operation;

•Accurate color reproduction: Supports ICC color management, natural gradients – ideal for high-end home textiles/sportswear large-scale printing.

2. AJ-1904TX Pro 1.9m Industrial-Grade Dye-Sublimation Printer – A Stable Choice for Batch Production

Tailored for industrial-grade mass textile printing, it excels in long-term high-volume production with "stability and durability":

•1.9m width fits mainstream fabrics: Works with T-shirts, sweatshirts, sofa covers – no extra trimming needed;

•Stable output: 4 EPSON 13200-A1 printheads, max speed 110㎡/h; dual servo drive + auto correction system ensures ≤0.2mm pattern positioning accuracy in long-term use;

•Enhanced durability: Nozzle dust cover + full dustproof design adapts to complex workshops, boosting nozzle lifespan by 30% vs conventional models;

•Cost-effective operation & maintenance: Compatible with universal thermal sublimation inks (cuts consumable costs by 15%) + ink circulation system minimizes waste.

3. AJ-6204 DTF Super T-shirt Digital Heat Transfer System – Industrial-grade Mass Production

For large-scale clothing/accessory customization, this system integrates the full process of "printing-toner application-curing-dual-station hot pressing":

•2-4 EPSON i3200-A1 printheads, 600mm width (fits mainstream fabrics);

•Dual powder tanks + intelligent powder level sensor (anti-leakage/waste), ≥20% higher powder utilization;

•Supports cotton/nylon/chemical fiber/leather; customizes T-shirts/sweatshirts/backpacks, etc. No pre-treatment (vs DTG), cost only 1/5 of foreign equivalents.

4. AJ-301 Desktop DTF Desktop T-shirt Heat Transfer System – The Top Choice for Small Business Startups

Tailored for small stores and individual entrepreneurs, this desktop device features a compact design and smart functions to lower customization barriers:

•Compact desktop size: Only 650mm×450mm×380mm, saves space for flexible placement in small stores/studios;

•Smart easy operation: Mobile APP remote control + WiFi printing – no computer needed; upload images via phone to start, beginner-friendly;

•Efficient small-batch output: 300mm width (F1080 printhead) for T-shirts, hats etc.; 12㎡/h in 6pass mode; built-in ink level alarm + auto cutting, 20-30 customized pieces per batch;

•Low-cost entry: Compatible with universal DTF films/inks (15% lower consumable costs) + ink circulation system to minimize waste – ideal for entrepreneurs starting personalized customization businesses.

II. Digital Label Zone: AJ-330E Multifunction Digital Label Printer

Core Advantages: Streamlined Labeling | Efficiency Gains | Cost Savings | Superior UV Print Quality | Customizable Designs | Integrated Functionality

•Uses UV digital inkjet (no plate-making, higher efficiency). Equipped with 2Xi1600-U1 industrial printheads, supports 110-330mm width, and offers CMYK+W/CMYK for wider applications.

• Combines printing, laminating, die-cutting, waste stripping, slitting, and winding in one compact machine, meeting more personalized needs.

•High-resolution UV printing ensures clear, sharp labels for easy reading.

•Built-in variable data plugin for custom labels; supports auto variable numbering to identify labels and design pro labels fast.

III. Wide-format UV Printing Zone: UV Roll-to-Roll Printer Series

Covering outdoor advertising, architectural decoration, and other scenarios, the entire series adopts UV-curable ink + LED curing technology.

•AJ-1904UV (High-Efficiency Model): 4 i3200-U1 printheads, 1.9m wide printhead, 48㎡/h print speed, supports hot stamping and gloss varnish effects, suitable for brand car wraps and large billboards;

•AJ-1602UV (Neon Edition) : 2 i1600-U1 printheads, 1.6m wide print, neon color printing + backlight effect, suitable for bar and exhibition atmosphere decoration;

•AJ-3202UV (Large Format): 3.2m ultra-wide format, 22㎡/h printing speed, suitable for architectural murals and curtain fabric printing.Visit Booth D04 – Experience cutting-edge printing tech firsthand.

AINJKET’s key annual exhibition – DPES CHINA 2026 – offers a prime chance to experience "3D Silicone & TPU Dual Solution" and "High-Speed Wide-Width Printing" technologies firsthand, and engage deeply with our technical team. Whether you’re a home textile manufacturer needing high capacity or a startup seeking low-cost entry, suitable solutions await at Booth D04.

•Dates: March 10-12, 2026

•Venue: Guangzhou International Convention and Exhibition Center

•For more details: Visit www.ainkjet.com or follow AINJKET’s official www.youtube.com for real-time updates.

See you in Guangzhou this March! AINJKET looks forward to co-creating a future of new printing technology with you at DPES CHINA 2026!

content is empty!